P266G - Improving Thickener Technology

Value

AUD $2,908,500

Commencement Date

September 2012

Duration

3 years

Program Manager

Gray Bailey

Research Providers

CSIRO - Dr Phillip Fawell; University of Melbourne - Professor Peter J Scales

Sponsors

Alcoa World Alumina; Anglo American; Aughinish Alumina Limited; BASF Mining Solutions; Cytec Industries Inc; Tenova Delkor; FLSmidth Minerals; KEMIRA Chemicals IncMMG ; Newcrest Mining Limited; Outotec Pty Ltd; Senmin South Africa (Pty) Ltd; Shell Canada Energy; Teck Metals Ltd; Total E&P Canada; WesTech Engineering Inc

PROJECT SUMMARY

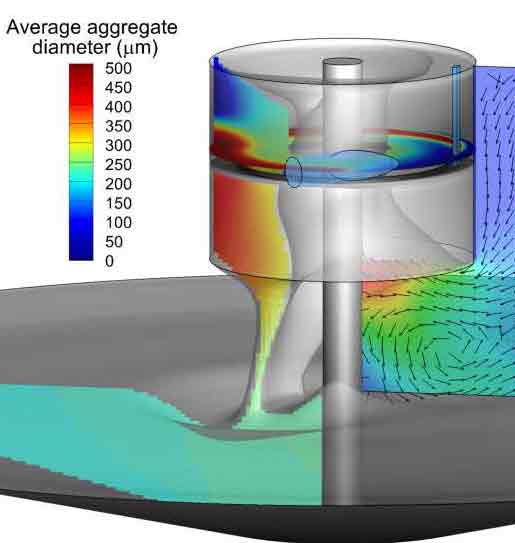

World-leading computational fluid dynamics (CFD) feedwell modelling capabilities are applied to optimise feedwells of thickeners in mineral processing applications across all commodities for operating sponsors, and to supplier sponsors seeking to test new feedwell designs or optimise flocculant addition. The impact of bed height, rake design, and aggregate sedimentation are also studied.

HIGHLIGHTS/DELIVERABLES/ADDITIONS

Benefits delivered include:

- Options to maximise feedwell performance through modified designs, to consideration of different flocculants and operating conditions.

- Further enhancement of the P266 guidelines on how design features, process conditions, shear-induced dewatering and control strategies affect thickener performance.

- Exclusive access to a full thickener CFD model for optimising operating conditions, design evaluation and problem-solving.

- Exclusive access to project resources (Online Thickener Self-appraisal Tool, Knowledge Base and process models) and to the research team for site appraisals of thickeners and resolution of specific problems.

- Improved thickener control strategies to address operational challenges (e.g. compensating for input disturbances, handling of multiple control objectives).

- Extensive technology transfer through the wide range of tools available on the project website