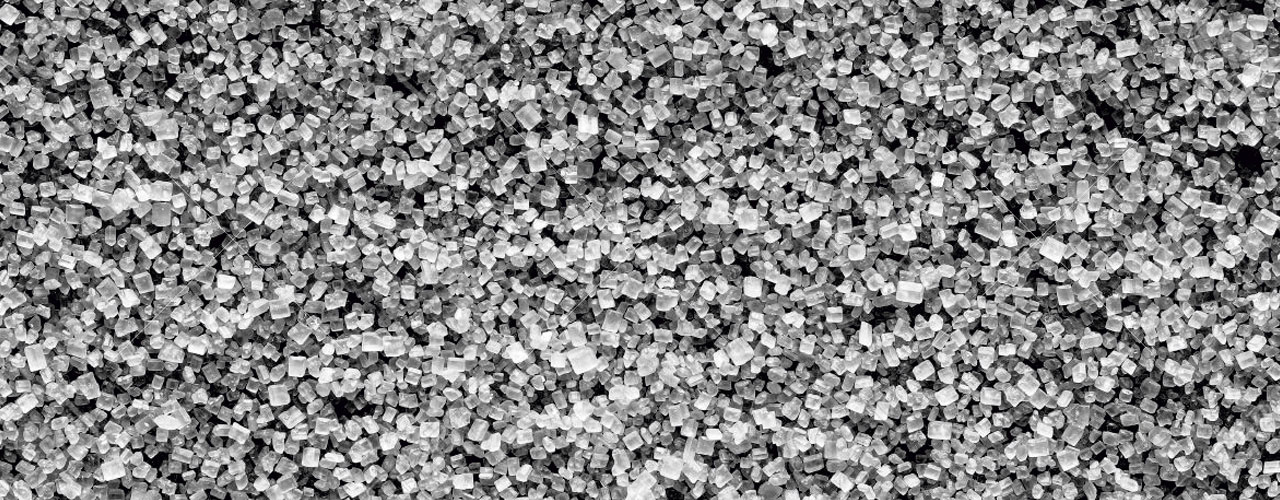

Mineral Processing

P009P - Mineral Processing

VALUE

AUD 13,283,010.00

COMMENCEMENT YEAR

2012

DURATION (YEARS)

4

COMMENCEMENT MONTH

April

STAGE

Complete

PROGRAM MANAGER

Terry Braden

RESEARCH PROVIDERS

Julius Kruttschnitt Mineral Research Centre (JKMRC)

Chalmers University of Technology

CRC ORE (Optimising Resource Extraction)

Hacettepe University (Benzer)

Universidade Federal do Rio de Janeiro

University of Cape Town

SPONSORS

Alcoa of Australia Limited, Anglo American Plc, AngloGold Ashanti Limited, Barrick Gold Corporation, BHP Billiton Base Metals, COREM, FLSmidth Minerals, LKAB,Lonmin PLC, Magotteaux Australia Pty Ltd, Metso Process Technology & Innovation, MMG Limited Mount Isa Mines, Newcrest Mining Limited, Newmont Mining Corporation, Outotec SEAP, Polysius AG, Rio Tinto Technological Resources Pty Ltd, Russell Mineral Equipment, Senmin International (Pty) Ltd, SGS, Bateman Sub Saharan Africa, Teck Resources Limited Vale Australia

PROJECT SUMMARY:

P9P delivered a more comprehensive range of models, as compared to P9O, as well as the standards and techniques for particle characterisation (composition and spatial arrangement of minerals) required as model inputs. Ore characterisation at the front end of the process will increasingly replace the traditional time consuming and expensive measurement of ore properties such as hardness, density, size distribution and floatability, required for the current models of the unit operations.

HIGHLIGHTS / DELIVERABLES / VALUE ADDITIONS:

These developments will, for the first time, link all unit operations so that the effects of changes in one area can be simulated and compensated for in other parts of the circuit. This integration of unit operation models will allow true overall process improvements to be identified. The P9P project will be executed with a case study approach in two parallel paths : 1) Implementation of case studies at specific sponsor sites using the integrated simulation platform based on fitfor- purpose multi-component models. 2) Develop and upgrade ore characterisation methods and models through continued data acquisition and validation. P9P will carry out extensive scientific research into the fundamentals of processes and unit operation phenomenon to underpin the development of unit operation models. Validation will be achieved by inplant surveys and analysis undertaken within P9P. Where possible and appropriate, P9P will also provide for the development of on-line instruments and measurement devices which will also facilitate the development and application of the models. These developments, fundamental understanding and site activities will of themselves greatly benefit sponsors by direct application, training and technology transfer.

Back