P260G - Flotation

VALUE

AUD 1,650,000.00

COMMENCEMENT YEAR

2014

DURATION (YEARS)

4

COMMENCEMENT MONTH

September

STAGE

Management

PROGRAM MANAGER

John Visser

RESEARCH PROVIDERS

Future Industries Institute

University of South Australia

SPONSORS

"Glencore Technology, Magotteaux Australia Pty Ltd, Newcrest Mining Limited, Newmont Mining Corporation, Outotec SEAP, Votorantim Metais

PROJECT SUMMARY:

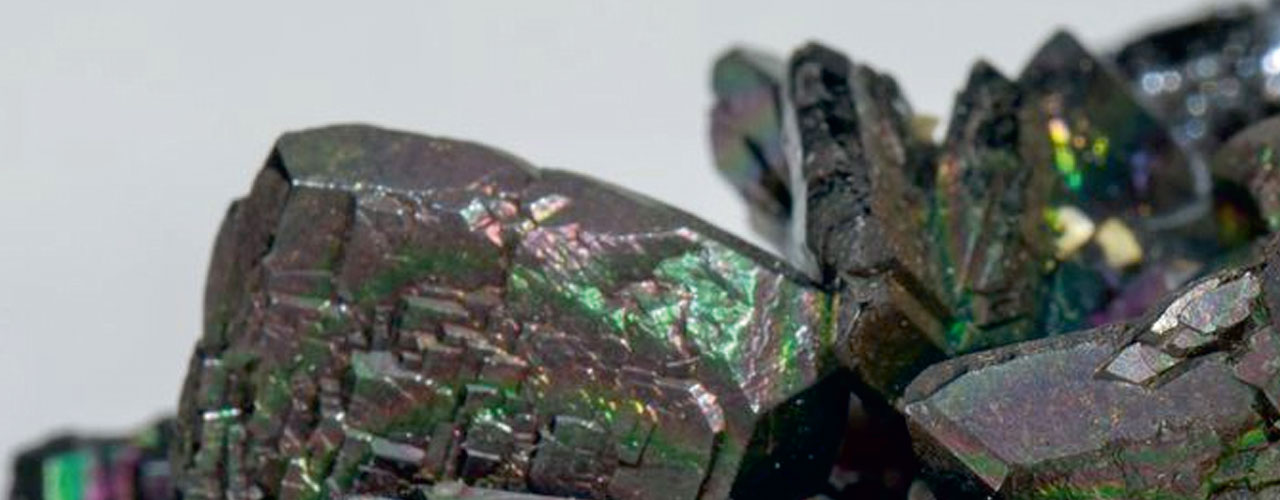

The P260 project, located at the Ian Wark Research Institute (The WarkTM) at the University of South Australia, has been delivering successful research and technology transfer outcomes to industry in mineral flotation for over 25 years. A principal focus of the P260 series of projects has been to develop tools and methodologies to improve understanding of factors which control the separation efficiency of minerals containing base metals in the flotation process. Importantly for sponsoring companies, the P260 series of projects has addressed problems related to site and ore specific characteristics at over 30 different sites world-wide. Based on the feedback received from the industry, the P260G project offers a range of focus areas of investigation, including:

- Deliver ore/site specific solutions to processing problems in parallel with research on process mechanisms

- Selectivity in sulphide mineral flotation (pulp chemistry, reagents, saline and marginal waters, sulphide and nonsulphide gangue depression, oxidised ores). Cu/Mo, Cu/Au, Zn/Pb, Ni, PGM – Py, Po, NSG depression, As rejection and/or control

- Regrind/Cleaning and flotation at fine sizes, with strategies for rejection of hydrophobic (e.g. activated Py, Po and NSG) and newly-liberated gangue

- Early gangue rejection (flotation at coarser grind - classification, de-sliming, reagents)

- Introduction, development and assessment of new unit technologies

- Hybrid/mixed processing (flotation of leach residues, physical separation / flotation, differential milling/classification/flotation, aggregation/flotation)

- Non-sulphide minerals flotation, e.g. phosphate, Li (spodumene), graphite, iron ore, REO’s (including from tailings) and other oxides

- Further development of the fundamental Wark Flotation Model into a modelling and simulation tool for practical use.

- Spectroscopy-microscopy (e.g. surface analysis-QEMSCAN) correlation and merging, and advanced, outcome-based statistical treatment of technique/unit operation/plant data

- Continue to enhance the technology and information transfer outcomes from all previous phases of the P260 project to sponsors operations and personnel.

- Develop useful characterisation tools (on-line and off-line), methods and protocols for use at sponsors operations and by sponsor personnel

- Training of high-quality post-graduates who are research - minded, outcome - focussed and have understanding of industry drivers. Opportunities also exist for both Technical Challenge and Supplier Sponsors to purchase Case Study investigations during the program to have other targeted site or sponsor specific studies undertaken. The project commenced in September 2014 (4 years). For Fy2014 - 15 Annual Report.

AMIRA P260G Flotation Project commenced in September 2014 and is the 7th extension project of the P260 series of projects, the pre-eminent global flotation research program. The principal focus of the P260 series of projects has been to develop tools and methodologies to improve understanding of factors which control the separation efficiency of minerals in the flotation process. Importantly for sponsoring companies, the P260 series of projects has addressed problems related to site and ore specific characteristics at over 30 different sites world-wide. The recently commenced P260G project is a 4 year program made up of a series of industry relevant

HIGHLIGHTS / DELIVERABLES / VALUE ADDITIONS:

The AMIRA P260 projects have delivered significant returns to its sponsors over the years and an independent assessment by RMDSTEM Ltd reported that the net value of AMIRA P260 to sponsors of the AMIRA P260 project has exceeded AUD1 billion by 2012 alone. This success, and continued industry support of P260, has been due to the projects' blend of strong, fundamentals and real world, mineral processing engineering. These have been applied to building understanding of flotation processes, mineral behaviour, and to addressing ore- and site specific sponsor process issues. Over the last 26 years, a series of AMIRA P260 mineral flotation projects conducted by the Ian Wark Research Institute (IWRI) at the University of South Australia have considerably advanced the understanding of flotation. Those projects have also provided sponsor companies with advice on improvements that have yielded improved concentrator performance challenged by variability in their feed ore characteristics. While P260G Flotation has been in progress for less than a year the research team has already improved the economics of a silver recovery process from the tailings at Tres Marias in Brazil and has gained early valuable insights for the case studies sponsored by specific companies in the consortium on the effects of grinding media debris and copper and gold flotation kinetics. The data gathered and insights gained are expected to lead to valuable sponsor outcomes as the project progresses for a further 3 years. Depending on the level of success of securing further leverage funds the project also has the objective of delivering further insights and data from case studies and collaborations focussed on:

- Coarse and coarse composite flotation, including fluidised-bed technology (Hydrofloat), for maximising value recovery, early rejection of gangue and reduced collector consumption and coarse primary grind optimisation for minimisation of energy usage.

- Methods to enhance selectivity against sulphide and non-sulphide gangue minerals, including depression of activated iron sulphides, and dispersion and depression of siliceous gangue minerals.

- Methods to increase recovery of fine value mineral particles including optimising oxidation product removal, grinding chemistry, and dispersion of fine particles.

- Methods of mitigating the negative impact of high salinity process waters on recovery and grade. The consortium is still open for further sponsors and it is likely that the sponsor group will increase and this will add to the 100 companies that have been involved in AMIRA P260 over the last 26 years and approximately 100 staff and research students that directly participated in this flagship AMIRA program.