P420E - Gold Processing

VALUE

AUD 3,793,500.00

COMMENCEMENT YEAR

2013

DURATION (YEARS)

3

COMMENCEMENT MONTH

April

STAGE

Complete

PROGRAM MANAGER

John Visser

RESEARCH PROVIDERS

Curtin University of Technology

Professor Jacques Eksteen

SPONSORS

AngloGold Ashanti Limited, Australian Gold Reagents Pty Ltd, Barrick Gold Corporation, Gekko Systems Pty Ltd, Harmony Gold Mining, Company Limited, Kemix (Pty) Ltd, Magotteaux Pty Ltd, Newcrest Mining Limited, Newmont USA Limited, Norton Gold Fields Limited, Orica Australia Pty Ltd, Randgold Resources, SGS Bateman Sub Saharan Africa, St Barbara Ltd

PROJECT SUMMARY:

This project commenced in April 2013 (3 years) and is sponsored by 8 gold mining companies and 6 supplier companies. The AMIRA Gold Processing Technology project has delivered industry focused research outcomes for 25 years. The current project has three themes:

1. Technology Transfer & Professional Development - focusing on plant surveys and inputs into models for plant optimization, coupled with workshops and courses for professional development of staff. This includes working with the online databases and SIMCIL (carbon in leach simulation) software.

2. Models and Optimization – focusing on the expansion of online models including for liberation-leach, gravity-flashfloat, leach adsorption models and new models for roasting which link mineralogy to thermodynamics. In addition, research continues into ore characterization and the development of a Code &Guidelines for baseline ore testing and characterization.

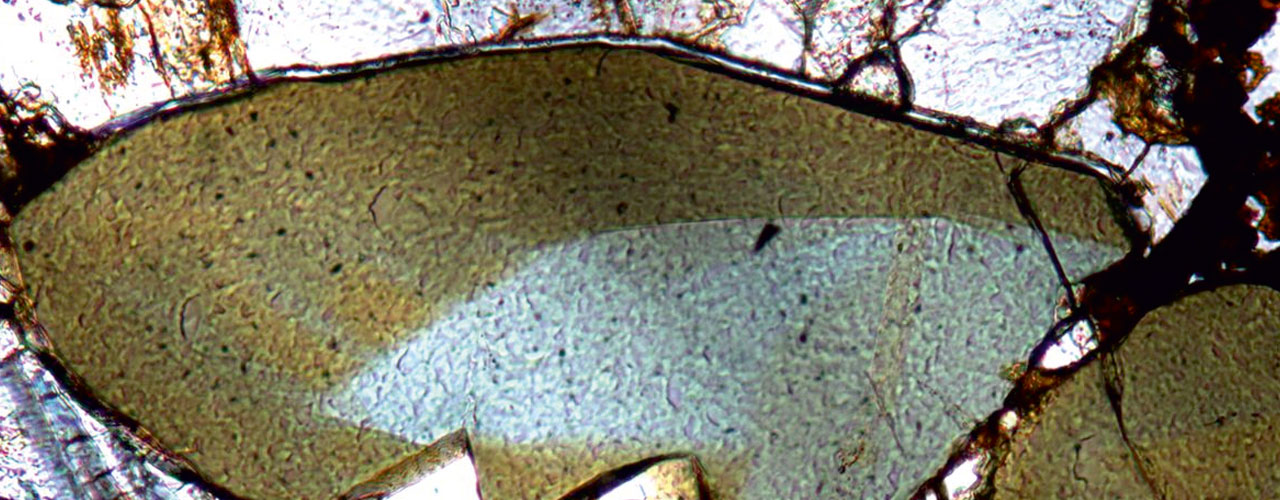

3. Future Ore Processing - a fundamental research component of the project focusing on the interactions of complex gangue minerals with the extraction of gold, with particular emphasis on Au-Cu, Au-Ag ores with As, Hg, S and Te contamination. This includes studying the loss mechanism of Au and Ag to tails in Au-Ag plants and Au in Cu-Fe-As-S tails.

HIGHLIGHTS / DELIVERABLES / VALUE ADDITIONS:

There have been 10 plant and 3 desktop surveys conducted and results presented for various members of the project, including the sharing of learnings across sponsors,

- Consulting to the major operating sponsors

- Eight technology transfer training event were provided to various site personnel teams

- Four regional technology transfer workshops have been held

- A range of simulation models have been developed for all sponsors, with some sites using the models and researcher aid to optimise their process circuits

- Some fundamental and applied research has been delivered in areas of; Pre-concentration: Coarse particle rejection New lixiviates created New leach/adsorption technologies produced New models of polymetallic Au-Cu-Ag systems written New models for integrated liberation-leach and gravity flash-flotation systems have been written, validated and calibrated The online process models for jigs are currently being overhauled. The team is busy quantifying the interactions between grinding media, process water and gold ores Approaches to arsenic removal for copper-gold concentrates have been carried out

- Useful guides and reports have been developed and written such as; Updates on the online industry practices survey Updates on the Good Industry practice guide for ore characterisation A manual written for the metallurgical management of copper-gold ores

- Identification and quantification for reduced cyanide use, with benefits being realised at a number of operations (Leonora (St Barbara), Hidden Valley (Morobe JV), Serra Grande (AGA))

- Recommendations that have led to improved Au recovery (Serra- Grande, AGA)

- Recommendations made, based upon lab work, for improved silver recovery (Hidden Valley, Morobe JV)

- Techno-economic evaluation of the SART circuit at Telfer (Newcrest) delivered

- Evaluation of the carbon management at Lihir operation (Newcrest) to resulted in significantly reduced soluble gold losses.

- Evaluation of the gravity-flash flotation circuit at Tongon completed, as well as the evaluation of flotation frother types and additions, • Identification, qualification and quantification of opportunities at Kalgold (Harmony Gold) realised

- Investigation of the factors driving slow leaching at Loulo (Randgold) leading to improved leaching conditions

- Survey carried out at Ballarat Gold Fields to support work around pre-concentration and coarse particle gangue rejection

- Plant survey of Kanowna Belle Gold Mine carried out to characterise process and samples used for grinding media interaction.