P705C - Improving Base Metal Electrowinning

VALUE

USD 1,665,000.00

COMMENCEMENT YEAR

2013

DURATION (YEARS)

3.75

COMMENCEMENT MONTH

November

STAGE

Management

PROGRAM MANAGER

Terry Braden

RESEARCH PROVIDERS

Missouri University of Science and Technology, Federal University of Minas Gerais (UFMG), Murdoch University University of Utah

SPONSORS

Anglo Operations Limited, Freeport-McMoRan Copper & Gold Inc., Industrie De Nora S.p.a., MMG Limited RSR Technologies Inc, Teck Metals Ltd, Votorantim Metais

PROJECT SUMMARY:

The P705C project was designed to address the key technology improvement needs of the copper, zinc and nickel electro-winning operations around the globe and to deliver outcomes that should improve operations using a collaborative multinational research team. The project contains four modules; Anode Processes; Cathode Processes; Current Distribution; and Technology Transfer. P705C involves four research providers from four countries on three continents. This will help ensure local expertise is maintained and train future engineers and technologists in electro-winning technology. The project is a highly focused three-year project with the goals of reducing energy consumption, improving capital utilization, reducing acid mist and troubleshooting assistance. These goals will be achieved through the delivery of fundamental knowledge, prototypes, an empirical energy consumption model and operator training. Four of the biggest challenges facing electrowinning operations are:

- increasing energy costs

- increasing material costs

- acid mist and

- less experienced engineers and operators.

HIGHLIGHTS / DELIVERABLES / VALUE ADDITIONS:

AMIRA’s P705C project was specifically designed to help address each of these concerns while providing additional benefits. These include an online troubleshooting guide, guidance on operational changes to reduce acid mist, a method to perform a trade-off study between cobalt concentration and electrical energy consumption, data on the effect of specific impurities on anode corrosion and cathode deposits, and onsite training of over 100 personnel on four continents. In fact, one sponsor reported that improvements made based on the P705 project resulted in US$3.3 million annual savings.

The major accomplishments achieved during the AMIRA P705C Project are:

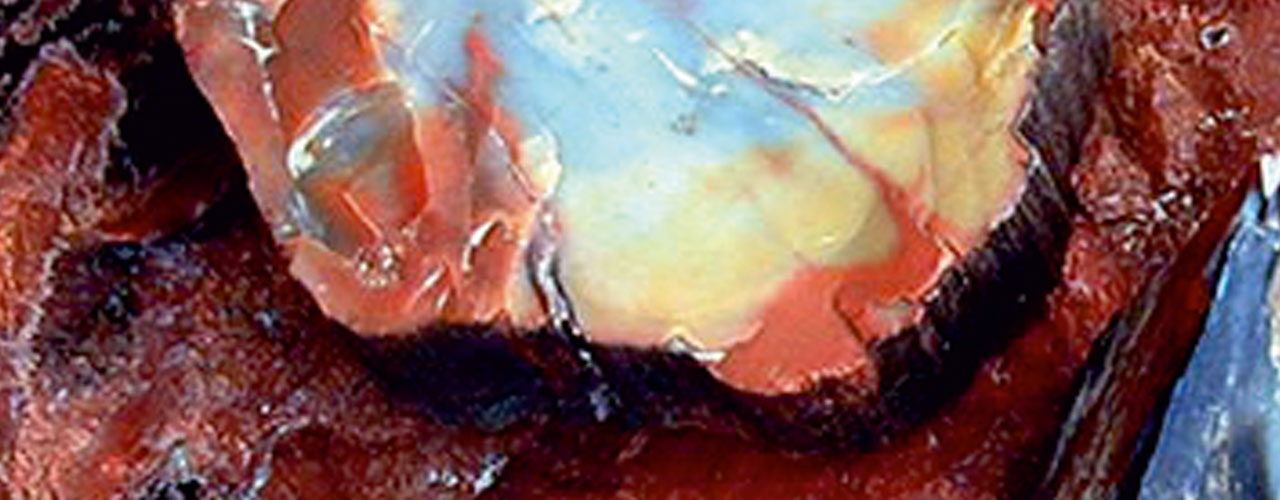

1. Acid Mist in Copper

- Measured effect of operating parameters on oxygen bubble size generation on Pb and MMO anodes and correlate to acid mist generation

- Determined the effect of operating parameters on acid mist generation.

- Discovered a surfactant that reduced acid mist as much as the current standard

2. Mn/Cl Ratio in Zinc

- Determined the optimal Mn/Cl ratio to minimize anode corrosion

3. Co/Mn/Power Outage Interaction

- Developed empirical model to predict energy consumption as a function of electrolyte Mn, Co and Fe

- Determined the effect of power outages on anode corrosion

4. 2020 EW Model

- Validated ability to predict the likelihood of short circuiting in copper electrowinning based on fundamental calculations

- Model ready to optimize energy consumption of electrowinning facility

5. Impurities/Additives in ZnEW and NiEW

- Measured the effects of operating parameters on energy consumption, deposit morphology, structure and nanohardness

- Developed cathode flexibility test

- Examined the effects of high concentrations of Mg in zinc

6. Reducing Stress in NiEW

- Determined effects of operating parameters and impurities using two methods

7. Technology Transfer

- 8 modules for drelectrowinning.com completed

- 6 site visits/ 5 webinars/ 30 case studies